Summit Electric Lights Up with a New ERP System Case Study

Case Study: Summit Electric Lights Up with a New ERP System

Question 1: Which business processes are the most important at Summit Electric Supply? Why?

There are many of business processes used by the Summit Electric Supply. The most important of these business processes is the ERP (Enterprise Resource Planning) system software from SAP. Summit Electric uses ERP system because scalability and inventory visibility were the main requirements of the Summit Electric operations. They kept these two data set up to date along with the information of the level of stock and inventory left in the store to make sure the shelf time was reduced. The system that maintained the inventory and the stock must be aligned with the SAP software because the sales and distribution along with the finance and materials management must be kept in check to progress with every project and day to day activities. The ERP system alignment with all the function also helps increase their distribution capacity.

At summit electric the most important and popular products is the batch management process. The company buys the products in reel of length of round 5000 feet that is later cut into different lengths as required. The demand of the different length can be different given at times and it is sometimes difficult to keep track of what product in what size is being sold more than the other. Through the use of batch management process the problem of the inventory of such product is reduced and sometimes completely eliminated.

The other business process is the SAP’s Net Weaver BW, a function that works as business intelligence for the company. The function reports and analyzes the current and forecast sales that helps sustain the inventory in the market and push sales further higher. The functions also help the company to evaluate its profitability in sales.

Question 2: What problems did Summit have with its old systems?

- Supplies were delayed

- The different categories were separated in the system making it complicated and difficult to manage

What was the business impact of those problems?

- The business was unable to keep track of its supply chain

- The company was only able to handle a few numbers of product range and locations

- The supply delay caused delay in the task and became more time consuming. The tasks took more time than needed.

Question 3: How did Summit’s ERP System improve operational efficiency and decision making? Give several examples.

ERP system at Summit Electric has improved the Summit’s Operational Efficiency and Decision Making. Now Summit operations are supported by

- Much faster distribution

- Time efficiency

- Simplified task and work

- Review of sticks easily

- Evaluation of profitability easily

- The system is more simple and easy

Question 4: Describe two ways in which Summit’s customers benefit from the new ERP system.

The customer can rely on the company for their needs and products with customization services involved. The on- site temporary summit warehouse save time for both sides and reduces the task completion details. The company easily creates parent-child relationship with the warehouse.

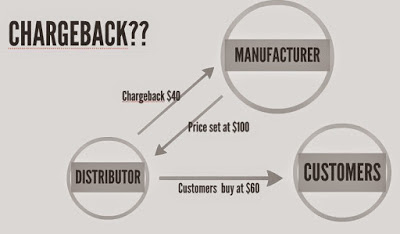

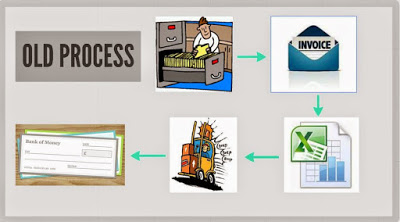

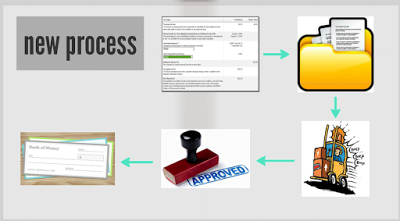

Question 5: Diagram Summit’s old and new process for handling chargebacks.